High Throughput Sequencing Platform (NGS)01

Based on the sequencing platform led by sequencer T series (DNBSEQ-T7, DNBSEQ-T20), we build a sequencing center with an annual throughput of Petabyte scale. It serves global research institutions and bio-breeding enterprises via providing high-quality full-process gene sequencing services, supporting scientific research and industrialization in hotspots such as bio-breeding, health, deep-sea life research, and others.

Spatiotemporal Omics Platform (STOmics)02

Stereo-seq, a spatiotemporal omics technology independently developed by BGI, captures mRNA from tissue section by stereo chips and restores the spatial location by utilizing the spatial barcode (Coordinate ID, CID), thus establishing a solid research foundation for further understanding the relationship between gene expression, morphology of cells and local environment. Stereo-seq is an in-situ panoramic technology with high throughput, ultra-high resolution and large field of view. It breaks through the limitations of traditional technologies and can displays the spatial gene expression patterns of animal and plant organs/tissues at sub-cellular resolution, realizing the panoramic display of cell Spatial gene expression.

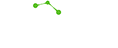

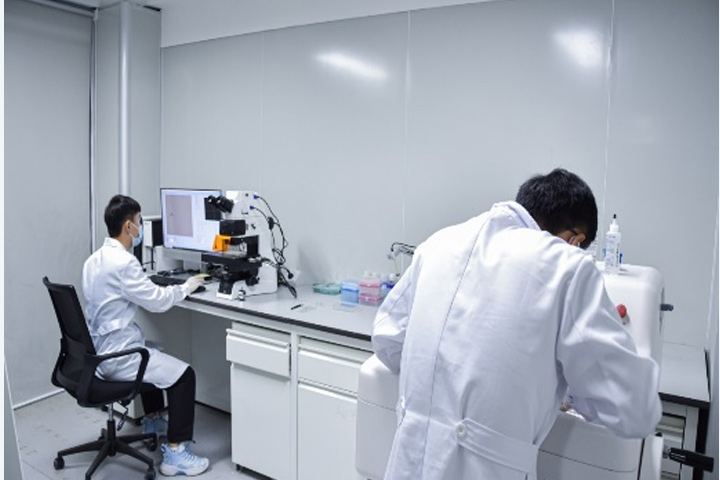

Microbial High-throughput Screening and Identification Platform03

Microbial high-throughput screening and identification platform comprises four functional modules: highly efficient mutation of microorganisms, microfluidic high-throughput screening, functional verification and rapid identification. The platform enables researchers to address the issues of the low mutation efficiency of microorganisms, large workload, long duration of primarily microbial screening, high cost, and lengthy functional verification. It has completed the development of the first microfluidic high-throughput cultivation and screening model for deep-sea microorganisms, reducing the time cost by at least 100 times. At present, the platform serves the microfluidic cultivation and screening of strains from extreme environments such as deep sea and has accumulated the preservation of 4,000 strains of annotated strains.

Genome Editing Platform04

The high-throughput automated nucleic acid manipulation platform replaces manual work with mechanized and automated production. The platform achieves full-process automation from explant induction, genetic transformation, to resistance screening and regenerated plant identification, including automated medium dispensing, etc. Our genome editing platform significantly reduces labor costs and contamination rates, enhances production efficiency and tissue culture quality. It contrib- utes to the improvement of researchers' capability and efficiency in creating crop mutant germplasm resource banks and supports the exploration of superior breeding genetic resources and the rapid cultivation of elite crop varieties.